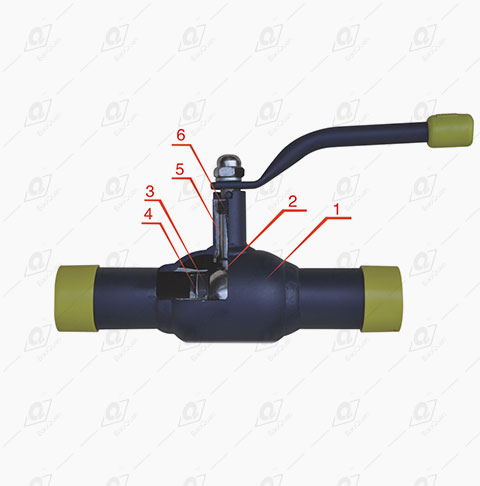

Fully welded ball valve cutting figure

结构特点

1.阀体采用无缝钢管压制成型

2.阀门的整体结构采用全焊接制造工艺,减少了外泄漏;阀门重量大大减轻,安装更便捷

3.采用弹性垫圈及碳纤维增强密封圈,可经受几万次往复运动无泄漏,保证阀门的使用寿命

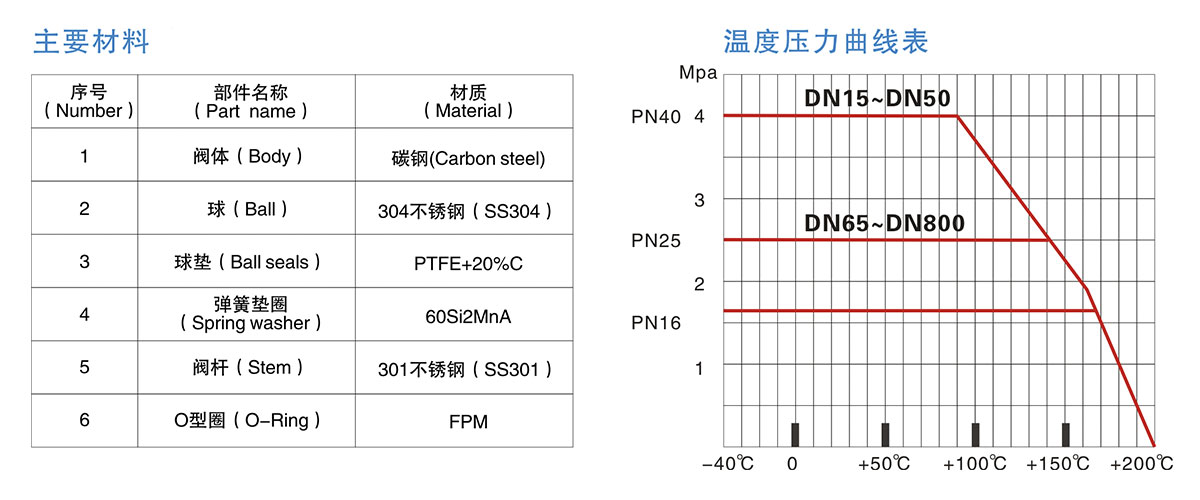

4.阀门的密封可以在-40℃-200℃的条件下连续使用而不会失效

5.连接方式有对焊、法兰、螺纹连接等形式,开启采用手柄、涡轮传动、电动等方式

6.长杆直埋焊接球阀可以深埋地下,不用设置阀门井,操作者只需在地上用手柄或涡轮传动机构操作即可,非常方便

7.全焊接球阀广泛用于城市集中供热、天然气输送管线、调压站等领域,是工程首选的阀门

1.Body is adopted for seamless steel pipe to the molding.

2.The overall structure of the body can reduce the external leakage by the full weld manufacturing process; the weight of the

valve is greatly reduced and installed much more conveniently.

3.To adopt the spring washer and carbon fiber seal ring, they can support hundred of thousands of times reciprocating motion. Thus there is no leakage; they ensure the service life of the valve.

4.The valve sealing can be used continuously without failure in the -40℃ to 200℃ situation.

5.There are many connecting methods, such as butt end, flange end and socket weld etc; there many open mode, such as handle, gear operation and electric etc.

6.Long stem buried welding ball valve can be deep-seated under ground; mean while don't set up underground valve control room. Operator can just use the handle or gear operation on the ground. It is very convenient.

7.Welded ball valve is widely used in urban central heating, natural gas transmission and regulator station and other areas. They are the top selection in construction project.

上一篇:V型球阀

下一篇:最后一篇